As an Amazon Associate I earn from qualifying purchases.

Our Associate portal can be found here

With each shot, the bolt carrier group or BCG is the part that moves back and forth. It’s the primary functioning component of your semi-automatic rifle, and proper selection can mean the difference in critical situations. But which are the best BCGs?

Since it’s the most complex and essential part of your rifle’s firing mechanism, you want the right BCG. The bolt and carrier group bears the brunt of gas pressure as it acts as your AR-15s action, housed between the lower and upper receiver. When looking at the best BCGs, factors to consider will include weight, hole size for the firing pin, coatings, bolt choice, and plating.

To help you put together a rifle you can rely on, and I will talk about the essential characteristics of the best BCG. As you read on, you’ll discover what is available and how to make the best buying decision.

What are Bolt Carrier Groups (BCGs)?

The bolt carrier group functions as a hammer to fire a round, fetch a new cartridge and expel the used one. Components of this versatile semi-auto rifle feature include a retaining pin, gas key, bolt cam pin, bolt assembly, firing pin, and carrier.

Your AR-15 uses direct gas impingement from the fired round to move the BCG back and forth. The movement facilitates three essential functions, including cycling, ejection, and reloading. With the BCGs firing capabilities, you don’t need to pull the charging handle or cock after each shot for semi-automatic rifles.

Bolt carrier groups come in two configurations alongside a couple of customizations. Differences occur mainly in the back end, where an M-16s carrier is longer than the AR-15s shorter but full-diameter tail section. While there’s also a collar-size difference due to the shrouded firing pin of an M-16, these variances in design come down to weight.

BCGs with the extra collar diameter weigh over an ounce more than their counterparts. While this is great, M-16 carries are sometimes treated as National Firearms Act or NFA Title II regulated items. However, thanks to the accessory market for BCG matches with weight identity and shrouded pin capabilities for your semi-auto rifle.

The Best BCGs: Our Top 5 Picks

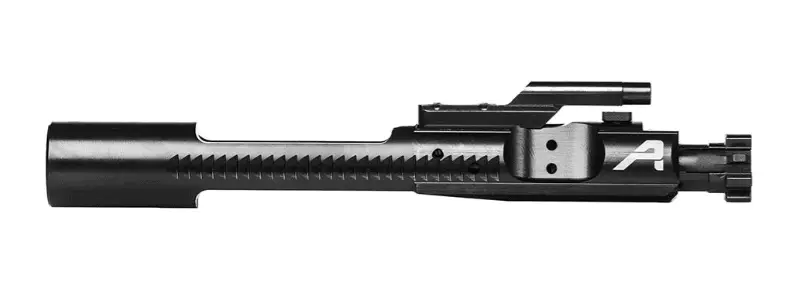

The best bolt carriers for your semi-automatic rifle are perfectly engineered and expertly machined. Aero Precision’s razor-thin tolerance levels for military specification standard BCGs mean there isn’t a margin for error. This aviation products and firearm component manufacturer oversees the design, development, manufacture, and finishing of all parts.

BCGs by Aero Precision have consistent loading due to their engineering processes that employ machining centers with sophisticated rail-guided robots and cutting-edge monitoring devices. For your user satisfaction, the company has invested in the continual production of high-quality BCG components.

The five best BCGs from Aero Precision include;

1. 5.56 Bolt Carrier Group, Complete, Phosphate

Aero Precision’s 5.56 Bolt Carrier Group, Complete is the perfect balance of reliability and lightweight. It’s expertly machined from one piece of mil-spec Phosphate steel. It then undergoes plating with black manganese phosphate on exterior surfaces that come in contact with oil under friction or heat to make it even more resistant to carbon build-up. The carrier comes pre-assembled so all you need is a good cleaning and nitride conversion for easy maintenance regardless of where your rifle goes into battle. Seriously, the durability couldn’t get much better with this baby!

The main features include;

Precision Engineered

This BCG features a mil-spec phosphate finish and is precision machined to exacting tolerances.

Durability

Features a carrier made from Carpenter 158 Tool Steel, and an 8620 steel with an M16 cut bolt.

High Quality

Manufactured in the USA by a company that specializes in high-quality AR15 parts and components.

2. 5.56 Bolt Carrier Group, Complete, Black Nitride

If black nitride is your preferred coating, this high-quality BCG from Aero Precision fits the bill for your AR-15 build. The bolt is machined from 9310 Steel while the carrier is 8620 Tool Steel, and the material is shot-peened. You don’t need constant cleaning and lubrication with this 5.56 Bolt Carrier Group’s finish which lowers operation friction.

A staked gas key and forward assist serrations for the carrier are other features of this M-16 cut BCG, weighing 11.52 ounces. Materials for this made in the US component are MPI and HPT test marked, while there’s an insert for a black O-ring on its extractor.

Pros

- Made from durable material

- Lightweight

- Reduced friction

- MPI tested and HPI marked

3. 5.56 Bolt Carrier Group, Complete, Nickel Boron

This is a BCG designed for the AR-15 platform but offers the M-16 shrouded firing pin design. The Nickel Boron Coated 5.56 Bolt Carrier Group features a bolt fashioned from 9310 Steel, with the carrier made of 8620 Steel. A manufactured in America component, this bolt carrier weighs 11.52 ounces and has forward assist serrations.

This 5.56 Bolt Carrier Group has mil-spec nickel boron coating on the bolt, carrier, and gas key as an upgraded Aero Precision. The staked key is forged and attached with Grade 8 connectors, while this BCGs bolt is MPI marked and shot-peened. Besides a tool steel extractor, there’s a black extractor for a Viton O-ring on this high-quality semi-automatic action.

Pros

- Durable construction

- Lightweight design

- Wear and corrosion resistant

4. 6.5 Grendel/6mm ARC Bolt Carrier Group, Complete, Black Nitride

This 11.52 ounce BCG has a bolt made from mil-spec Carpenter 158 Tool Steel and a carrier forged from 8620 Steel. The Aero Precision logo 6.5 Grendel/6mm ARC Bolt Carrier Group features a black nitride-coating. Its carrier features forward assist serrations while the bolt channel and gas key are chrome lined.

With its M-16 cut, this BCG has a properly staked gas key, while the type 2 .136 bolt face and bolt are shot-peened, MPI, and HPT test marked. The black nitride coating advances friction lowering for less lubricating and cleaning, while there’s a black O-ring insert on its high-quality steel extractor.

Pros

- Properly staked gas key

- Lightweight design

- Reduced friction

- Made from strong and durable materials

5. .224 Valkyrie/6.8 SPC Bolt Carrier Group, Complete, Black Nitride

The .224 Valkyrie is a 6.8 SPC carrier group with an M-16 cut and a black nitride finish for advanced lower operation friction. This BCG is made in the US and weighs 11.52 ounces. It also features a bolt and carrier made from mil-spec 9310 and 8620 tool steel.

Like other smart-engineered BCGs from Aero Precision, the .224 Valkyrie has forward assist serrations for the carrier and a properly staked gas key. You can see MPI and HPT test markings on the bolt material, which is also shot-peened. The Black Nitride 6.8 SPC Bolt Carrier Group features an insert on the extractor for an O-ring.

Pros

- Nitride finish reduces friction

- The BCG is lightweight, at only 11.52 oz

- Durable make

Factors to Consider When Buying the Best Bolt Carrier Groups

Optimum performance delivery should be your top priority when looking for a bolt carrier group for your semi-automatic rifle. Factors to consider will include the bolt material, steel, titanium, aluminum, or a composite hybrid.

Bolt Materials

Steel is further classified according to availability as well as easily machined variants. 9310 and 8620 steel and the high core strength Carpenter 158 steel are the recommended material for military specification BCGs.

Being tough and durable is not enough. Steel features excellent water and corrosion resistance capacities.

Shot Peening and Chrome Lining

Proper heat treating and shot peening of BCG materials will remove fatigue while imparting tensile strength. Inner chrome-lining is also a mil-spec requirement, where the inside is coated to increase life, resist corrosion, and facilitate maintenance.

High-Pressure Testing and Magnetic Particle Inspection

Ensure that your BCGs manufacturing materials have gone through rigorous test procedures to ascertain reliability. These include Magnetic Particle Inspection, MPI, to detect wear and fatigue, or High-Pressure Testing, HPT, which inspects cracks and other malfunctions.

Coating As an Essential BCG Selection Criteria

Various coatings are employed to give the best BCGs high friction-combating properties and water and corrosion resistance. Coatings ensure that your bolt carrier group operates smoothly and is easy to clean while resisting wear in operation.

Some of the standard BCG coatings you’ll see when looking for component additions to your semi-automatic rifle build include;

Phosphate

As a standard and widely used coating, phosphate is thinly applied to BCGs, offering extreme resistance to wear. The components are submerged in a vault of hot phosphoric acid with manganese and later baked at 200° F. This coating is also inexpensive. Still, it’s susceptible to fouling while proving problematic to clean.

Nickel Boron

Using an autocatalytic process that’s described as electrolyte-free, nickel boron coatings are deposited onto the steel. BCGs coated in this compound have heightened fiction lowering capacities while resisting corrosion. Nickel boron’s node structure acts well to dissipate heat, while this inexpensive coating cleans easily and has pleasant aesthetics.

Titanium Nitride

This offers BCGs excellent durability, plus slickness and smoothness in operation. Titanium nitride is tougher than nickel boron and phosphate coating, often resulting in longer carrier group service life. Coated steel has unmatched heat and corrosion resistance capabilities since nitride changes its molecular structure.

While not inexpensive, titanium nitride ensures that your BCG is smooth and hard. There is no compromise on quality or the aesthetic appeal that this coating offers your rifle build.

Ion Bond

All the above coatings are combined, or rather their more exemplary properties, to create a durable, heat, and water-resistant BCG finish. Compared to standard mil-spec bolt carrier group coatings, ion bonding is more costly, although its benefits undercut the price tag.

What’s the Difference between Full-Automatic and Semi-Automatic BCGs?

A full-auto BCG is longer than a semi-auto due to an additional rear lug that pushes down sear release for automatic fire bursts. That, however, does not affect how your semi-automatic rifle works. The only advantage to installing full-automatic BCGs is for any future full-auto conversion of your weapon if you live where this is legal.

With a negligible price difference, full auto BCGs tip the scale heavier due to the lug addition. A full-automatic bolt carrier group will work seamlessly with your semi-auto rifle, their added weight assisting in recoil reduction.

If you are looking to shed some weight, a semi-auto BCG is lighter and more compatible with AR-15 buffers. Another discrepancy to note is the shrouded firing pin, which a full-auto BCG features. Without a component disconnector pin, your rifle’s hammer will snag against the firing pin after each round.

Such instances of full-auto BCG conflict with semi-automatic rifles not only damage the firing pin but result in constant weapon jams. You can use small-diameter shrouded pin holes on your full-automatic carrier group that you’ve installed in your M-16 or AR-15.

How Do You Install a BCG into a Semi-Automatic Rifle?

Whether your choice is a full-auto or low mass semi-automatic BCG for your rifle builds, you’ll need to install it. Pairing your AR-15 with an individually tested bolt carrier group shouldn’t increase expenses but add longevity and operation preciseness.

Installing or upgrading your BCG involves three steps which include;

1. Checking your rifles chamber and magazine well for any live rounds that haven’t cleared

2. Disconnecting the upper receiver and placing it in the BCG while making sure the bolt is backed out before placement

3. Sliding the BCG into your rifle from beneath the charging handle and re-assembling the upper receiver

Conclusion

The bolt carrier group of your rifle is, in fact, your rifle. Therefore, this vital component should be the best for improved reliability, durability, reload speed, and action smoothness. The best BCGs follow military specifications of dimensions, tolerances, and coatings, while their gas keys aren’t loosened due to poor staking.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.

36 years old, been hunting and fishing my entire life – love the outdoors, family, and all kinds of hunting and fishing! I have spent thousands of hours hunting hogs and training hunting dogs, but I’m always learning new stuff and really happy to be sharing them with you! hit me up with an email in the contact form if you have any questions.